HEPA filters are designed to trap 99.97% of airborne particles as small as 0.3 microns, including pollen, dust, bacteria, and some viruses. They work by forcing air through dense fibers that cause particles to collide and stick, ensuring cleaner indoor air. Proper installation and maintenance are essential for peak performance. To find out how these filters really perform in real-world settings, explore the details below.

Key Takeaways

- HEPA filters are designed to capture at least 99.97% of airborne particles measuring 0.3 microns.

- Their high efficiency is verified through standardized aerosol challenge tests by authorized agencies.

- Proper installation, sealing, and maintenance are essential to ensure they meet the 99.97% removal rate in real-world use.

- They effectively trap common indoor allergens, bacteria, and some viruses, but not gases or particles smaller than 0.3 microns.

- Regular filter replacement (every 6-12 months) maintains optimal performance and ensures consistent particle removal.

What Are HEPA Filters and How Do They Work?

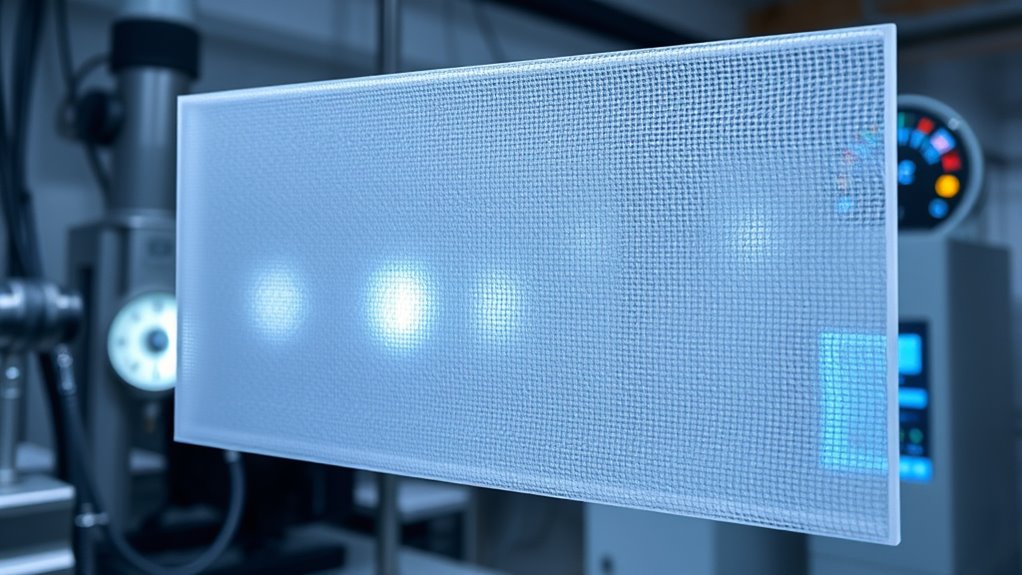

HEPA filters are highly effective air purification devices designed to trap tiny particles that can harm your health. They notably improve air quality by capturing contaminants like dust, pollen, pet dander, and bacteria. The key to their success lies in their filter efficiency, which is how well they remove particles from the air. HEPA filters use a dense mat of fine fibers that create a complex maze, forcing airborne particles to collide and stick to the fibers. This process ensures that even microscopic particles are captured, making the air cleaner and healthier to breathe. Because of their high filter efficiency, HEPA filters are trusted in environments requiring superior air quality, such as hospitals and cleanrooms. They truly stand out as reliable tools for better indoor air. Additionally, the filter maintenance process is crucial for maintaining their effectiveness over time.

The Origin and Standards of HEPA Filtration

Understanding the origin of HEPA filters helps you see how they became industry standards. You’ll learn about their development history, certification criteria, and testing procedures that guarantee their effectiveness. This knowledge reveals why HEPA filters are trusted for clean air in critical environments. Additionally, the rigorous testing standards for HEPA filters ensure their ability to trap airborne particles efficiently.

HEPA Development History

The development of high-efficiency particulate air (HEPA) filters traces back to the 1940s, when scientists aimed to create more effective filtration methods for protecting against airborne contaminants. This era marked a significant point in HEPA innovation, as researchers sought to improve upon existing filtration systems. The filtration evolution involved refining materials and manufacturing processes to achieve higher efficiency and durability. Originally developed for military and aerospace applications, HEPA filters quickly proved their effectiveness in trapping tiny particles like bacteria and dust. Over time, standards were established to define performance benchmarks, ensuring consistency across industries. Your understanding of HEPA’s development highlights how technological advances and rigorous testing have shaped the filters we rely on today for clean air and health protection. Additionally, advancements in filtering materials have contributed to increasing the efficiency and lifespan of HEPA filters, making them even more reliable for various applications.

Industry Certification Criteria

As HEPA filters became more widely adopted across industries, establishing reliable standards for their performance became a priority. These industrial standards ensure filters meet consistent quality benchmarks, giving you confidence in their effectiveness. Certification processes help verify that filters adhere to strict criteria, including particle removal efficiency and durability. The origins of these standards trace back to rigorous testing protocols. Key aspects include:

- Defining minimum filtration efficiency levels

- Setting allowable pressure drops

- Establishing testing methods for particle challenge

- Certifying filters through authorized agencies

- Regular re-evaluation for compliance

- Performance validation is essential to ensure filters meet high standards consistently.

These criteria guarantee that HEPA filters perform reliably across applications, from healthcare to manufacturing. By adhering to recognized standards, manufacturers can validate their products, ensuring you get filters that truly meet high-performance expectations.

Standard Testing Procedures

Standard testing procedures form the foundation for ensuring HEPA filters meet consistent performance criteria. These procedures evaluate filtration efficiency by measuring how well filters trap airborne particles, typically at 0.3 microns. You’ll find that testing also considers airflow dynamics, ensuring that filters maintain proper airflow without excessive pressure drops. Certification agencies like IEST and HEPA standards specify precise methods for these tests, including controlled environments and standardized aerosol challenges. By adhering to these procedures, manufacturers demonstrate that their filters consistently meet the 99.97% efficiency benchmark. Testing protocols are designed to simulate real-world conditions, ensuring filters perform reliably across various applications. This rigorous testing guarantees that filters not only trap particles effectively but also function reliably under real-world operating conditions, giving you confidence in their performance across diverse applications.

Testing Methods for HEPA Efficacy

To evaluate HEPA filter performance, you’ll want to focus on particle size testing to confirm it traps particles as small as 0.3 microns. Airflow measurement techniques help guarantee the filter maintains proper airflow without leaks. Together, these methods verify that your HEPA filter meets the necessary efficacy standards. Additionally, understanding the Best Anime Movies can provide a relaxing break from technical evaluations.

Particle Size Testing

How do researchers determine whether a HEPA filter effectively traps tiny particles? They use particle size testing to assess filter performance, focusing on the smallest airborne particles that impact air quality. This testing involves generating aerosols with specific particle sizes and measuring how many pass through the filter. Key aspects include:

- Selecting standardized test aerosols, like sodium chloride or dioctyl phthalate

- Using particle counters to detect airborne particles before and after filtration

- Comparing particle counts to evaluate filtration efficiency at different sizes

- Ensuring consistent test conditions that mimic real-world airflow and filter design

- Verifying that the filter meets the 99.97% efficiency benchmark for 0.3-micron particles

- Market growth projected at over 40% CAGR in AI tech by 2025, which influences innovations in testing methods and standards.

This process helps confirm whether a filter maintains high air quality standards and performs as expected.

Airflow Measurement Techniques

Ever wondered how researchers verify that a HEPA filter allows the correct amount of airflow while maintaining its filtration efficiency? They use airflow measurement techniques that assess airflow patterns and pressure differentials across the filter. These methods ensure the filter performs properly under different conditions. By measuring pressure differentials, you can determine if airflow is uniform or if there are bypasses or dead zones. Devices like anemometers, manometers, and airflow hoods are common tools. Here’s a quick overview:

| Technique | Purpose | Key Metric |

|---|---|---|

| Face velocity measurement | Assess airflow through filter surface | Velocity in meters/sec |

| Pressure differential | Detect airflow resistance | Pascals (Pa) |

| Smoke visualization | Visualize airflow patterns | Flow uniformity |

Additionally, understanding the HEPA filtration process helps in interpreting these measurements, as it indicates the filter’s ability to trap airborne particles effectively.

Real-World Performance Versus Laboratory Claims

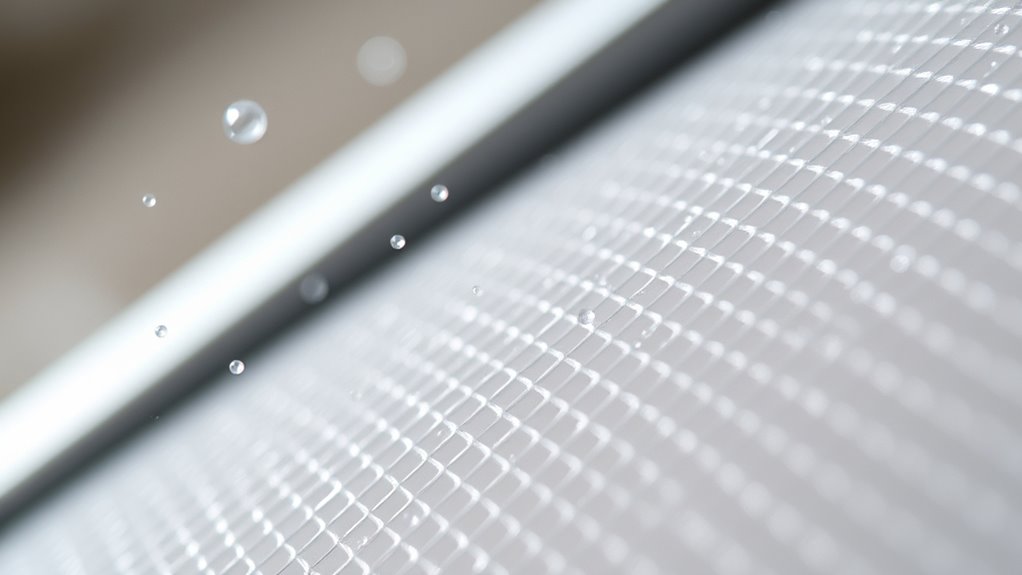

While laboratory tests often show HEPA filters capturing 99.97% of particles, their real-world performance can differ markedly. Factors like installation, maintenance, and positioning influence how well they perform indoors. In practical settings, air quality improvements depend heavily on these elements. Established brand reputation can also play a role in ensuring filter quality and performance consistency. Proper filter sealing prevents bypasses that reduce effectiveness. Regular filter replacement maintains high filtration efficiency. Room size and airflow patterns affect particle capture. Indoor allergens can bypass filters if not properly fitted. External sources of pollution can overwhelm the filter’s capacity. Understanding these variables helps you assess whether your HEPA filter truly enhances indoor air quality. While they excel in lab conditions, real-world results depend on proper use and environment, impacting their ability to trap airborne particles effectively.

Common Airborne Particles Captured by HEPA Filters

Have you ever wondered what types of particles a HEPA filter can trap? These filters are highly effective at capturing common airborne particles like indoor allergens, including pollen, mold spores, pet dander, and dust mites. They also trap airborne bacteria and some viruses, helping reduce bacteria circulating in your indoor environment. HEPA filters work by trapping particles as tiny as 0.3 microns with a 99.97% efficiency, making them essential for allergy sufferers and those seeking cleaner air. You’ll notice a significant reduction in irritants and airborne contaminants, creating a healthier indoor space. While they don’t target gases or odors, HEPA filters excel at removing the most common airborne particles that impact your respiratory health. Additionally, understanding AI security vulnerabilities can help improve the safety and reliability of the smart devices that often incorporate HEPA filter technology.

Limitations and Potential Gaps in HEPA Filtration

Despite their high efficiency, HEPA filters have notable limitations that can affect their overall effectiveness. Filtration gaps may occur when particles are smaller than 0.3 microns or when airflow bypasses the filter, reducing overall capture. Nanoparticle challenges arise because particles at the nanoscale can slip through or navigate around filter fibers more easily. Additionally, HEPA filters may struggle with:

- Filtration gaps caused by improper installation

- Reduced efficiency over time due to clogging

- Limited effectiveness against ultrafine nanoparticles

- Potential for airflow bypass around the filter edge

- Difficulty trapping certain volatile or gaseous pollutants

Understanding these gaps helps you recognize that, while HEPA filters are highly effective, they’re not foolproof, especially when dealing with nanoparticles or installation issues. Filtration efficiency can decrease over time as particles accumulate, further diminishing their protective capability.

Comparing HEPA Filters to Other Air Purification Technologies

How do HEPA filters compare to other air purification technologies regarding effectiveness and application? HEPA filters excel in particle removal rates, capturing 99.97% of airborne particles down to 0.3 microns. Other technologies, like activated carbon filters, target odors and gases but often lack the same air filter efficiency for particles. UV purifiers deactivate microbes but don’t physically remove particles as effectively. Here’s a quick comparison:

| Technology | Particle Removal Rates | Best Use Case |

|---|---|---|

| HEPA Filters | 99.97% at 0.3 microns | Allergies, asthma, dust |

| Activated Carbon | Odor and gas control | Smoke, VOCs |

| UV Purifiers | Microbial deactivation | Bacteria, viruses |

| Ionizers | Particles charged | Large rooms, spaces |

| Electrostatic Filters | High efficiency | Cost-effective filtration |

Additionally, advancements in filtration technology continue to improve the effectiveness and application of these devices.

Tips for Choosing Effective Air Purifiers With HEPA Filters

Choosing the right air purifier with a HEPA filter involves understanding your specific needs and the environment where it will be used. To maximize air quality, select a model suited for your space size and pollutant levels. Consider the filter lifespan, as longer-lasting filters reduce maintenance and costs. Look for units with a clean air delivery rate (CADR) that matches your room’s air quality demands. Pay attention to noise levels during operation. Also, check for features like adjustable settings and air quality sensors for ideal performance. Ensuring your device is capable of trapping airborne particles effectively can make a significant difference in indoor air quality.

Maintenance and Longevity of HEPA Filters

Proper maintenance is essential to guarantee your HEPA filter continues to perform effectively and lasts as long as possible. Regular filter replacement is key; most filters need changing every 6 to 12 months, depending on usage and air quality. Neglecting timely replacement can reduce filtration efficiency and increase strain on your air purifier. When considering cost, keep in mind that investing in quality filters may cost more upfront but can extend the filter’s lifespan and improve overall air quality. Check manufacturer guidelines for recommended replacement intervals and avoid using a dirty or clogged filter, which can lead to higher energy bills and decreased performance. Staying on top of maintenance ensures your HEPA filter remains effective, saving you money and protecting your health in the long run. Additionally, using proper airflow around the unit can significantly enhance its performance and longevity.

Frequently Asked Questions

Can HEPA Filters Remove Viruses and Bacteria Effectively?

Think of HEPA filters as vigilant gatekeepers, blocking unwanted visitors. They effectively trap viruses and bacteria, reducing viral transmission and bacterial filtration in the air. While they don’t eliminate all pathogens, they markedly lower the risk of airborne spread. Using HEPA filters in your space helps create a safer environment, especially during outbreaks, by capturing most tiny infectious particles and preventing them from circulating freely.

How Often Should HEPA Filters Be Replaced for Optimal Performance?

You should replace your HEPA filter based on its filter lifespan and replacement frequency recommendations, typically every 6 to 12 months. Factors like air quality, usage, and environment influence this schedule. Regularly check for signs of dirt or reduced airflow, which indicate it’s time for a change. Proper replacement guarantees your filter continues to trap airborne particles effectively, maintaining ideal performance and indoor air quality.

Do HEPA Filters Work Well in Humid or Damp Environments?

You might think HEPA filters are invincible, but humidity interference can really weaken their effectiveness. In damp environments, moisture accelerates filter degradation, making them less efficient over time. Excess humidity can cause particles to stick or clog the filter, reducing airflow and trapping capacity. So, while HEPA filters work great in dry conditions, damp settings demand more frequent replacements and careful maintenance to keep your air pure.

Are There Any Health Risks Associated With HEPA Filter Fibers?

You might wonder if there are health risks from HEPA filter fibers. Usually, HEPA filters are safe because they’re made to prevent fiber inhalation and rarely shed fibers into the air. However, poor-quality or damaged filters can shed fibers, potentially causing irritation or respiratory issues. To stay safe, regularly replace filters and choose reputable brands. Proper maintenance minimizes any risk related to filter shedding or fiber inhalation.

Can HEPA Filters Eliminate Odors and Chemical Pollutants?

You might wonder if HEPA filters can eliminate odors and chemical pollutants. While they excel at trapping airborne particles, they aren’t designed to remove odors or gases effectively. To improve your air quality, consider using activated carbon filters alongside HEPA filters. Regular filter maintenance is vital to guarantee peak performance, so replace or clean filters as recommended. This combination helps you breathe cleaner, fresher air indoors.

Conclusion

Think of HEPA filters as vigilant guardians, silently standing guard against airborne threats like a fortress defending its domain. While they’re highly effective at capturing 99.97% of particles, remember they’re part of a larger battle against indoor air pollutants. Regular maintenance and choosing the right purifier ensure your air stays pure, like a clear mountain stream. Ultimately, understanding their limits helps you make smarter choices for healthier living—because clean air is your sanctuary.