Carbon filters and activated charcoal are related but not the same. Carbon filters use activated charcoal to trap gases, odors, and pollutants through adsorption, often in air or water purification systems. Activated charcoal is the material itself, made from burned organic materials with a highly porous structure. Knowing their differences helps you choose the right filter for your needs. Keep exploring to discover more about how these filtration methods work and where they’re most effective.

Key Takeaways

- Carbon filters often contain activated charcoal but can include other materials, making them a broader category.

- Activated charcoal is a specific form of carbon used primarily for adsorption of gases and odors.

- Both utilize adsorption, but “carbon filter” refers to the device, while “activated charcoal” is the material inside.

- Carbon filters are designed for air and water purification, with activated charcoal being a common filtering component.

- Not all carbon filters are made solely of activated charcoal; some may use different carbon-based substances or composite materials.

What Are Carbon Filters and How Do They Work?

Carbon filters are devices that clean air or water by trapping impurities through a process called adsorption. In air purification, they effectively remove odors, volatile organic compounds, and gases. When contaminated air passes through the filter, pollutants adhere to the surface of activated carbon, preventing them from recirculating into your environment. This process relies on chemical absorption, where the carbon’s porous structure attracts and holds molecules. As a result, the air becomes fresher and safer to breathe. Carbon filters are widely used in HVAC systems, air purifiers, and water treatment units. By harnessing chemical absorption, they target a broad range of harmful substances, making them a versatile solution for improving air quality and reducing airborne contaminants. Additionally, advancements in automation in business are enhancing the efficiency of manufacturing and maintenance processes for these filters.

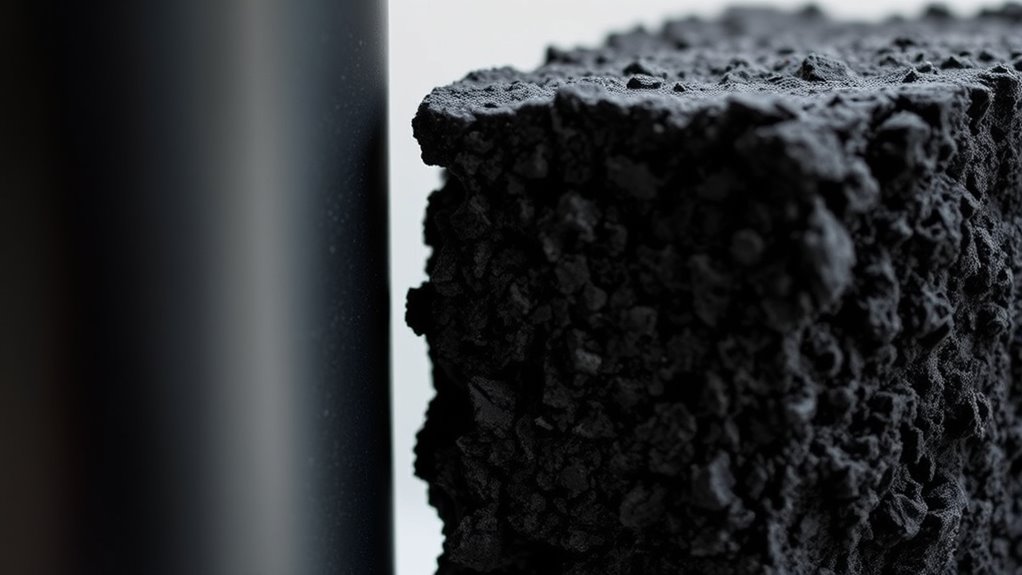

The Composition and Manufacturing of Activated Charcoal

Activated charcoal, the key material in many filtration systems, is produced through a specialized process that enhances its porous structure. This process involves carbonization and activation, which create a network of pores that increase its surface area and adsorption capacity. As a result, activated charcoal effectively captures contaminants. The manufacturing process typically includes:

- Selecting raw materials such as wood, coconut shells, or coal.

- Carbonizing the material at high temperatures to remove volatile compounds.

- Activating the carbon through physical or chemical methods to develop pore structure.

- Grinding and shaping the activated charcoal into the desired form for filtration.

These steps optimize pore structure and surface area, making activated charcoal highly efficient for trapping impurities and supporting effective filtration. Ongoing advancements in machine learning algorithms are also helping to improve manufacturing processes and product quality in this industry.

Key Differences in Functionality and Application

While both carbon filters and activated charcoal are used to improve water and air quality, they differ markedly in their functionality and applications. Carbon filters are designed with specific pore structures to target certain contaminants, making them effective for filtration systems that require consistent performance. Activated charcoal, on the other hand, acts mainly through adsorption, pulling impurities onto its surface. This means the filter lifespan of carbon filters depends on usage and the contaminants present, requiring regular replacement to maintain effectiveness. Maintenance requirements for activated charcoal are minimal but essential; once it’s saturated, its ability to adsorb diminishes, and it needs replacing. Understanding these differences helps you select the right solution for your needs, ensuring peak performance and safety. Additionally, filter lifespan can vary significantly based on the volume of contaminants and the frequency of use, so monitoring performance is key.

Situations Where Each Is Most Effective

Choosing the right filtration method depends on the specific situation and contaminants you’re dealing with. For air purification, activated charcoal filters excel at removing odors, volatile organic compounds (VOCs), and gases. Conversely, carbon filters are more suited for water treatment, especially when targeting chlorine, sediments, and certain organic compounds. Consider these scenarios:

- You need odor removal in indoor air — use activated charcoal filters.

- Water contains chlorine or sediment — opt for carbon filters.

- Air purification for VOCs and gaseous pollutants — activated charcoal is most effective.

- Water treatment where chemical contaminants are present — carbon filters work best.

- The contrast between filtration technologies influences the choice for specific contaminants, ensuring optimal effectiveness.

Understanding these applications guarantees you select the most effective filtration method for each situation, maximizing air purification and water treatment efficiency.

Choosing the Right Filtration Method for Your Needs

Selecting the right filtration method depends on identifying the specific contaminants you need to remove and understanding the environment in which you’ll use it. For air purification, consider whether you need to eliminate airborne particles or chemical vapors. HEPA filtration effectively removes particles like dust, pollen, and pet dander, while carbon filters excel at chemical absorption, effectively removing gases, odors, and volatile organic compounds. Activated charcoal, with its high surface area, is ideal for chemical filtration but may be less effective against larger particulates. If your priority is improving indoor air quality by reducing odors and chemical pollutants, a filtration system using activated charcoal might be best. However, if you’re targeting dust, allergens, or biological particles, a different filter may suit your needs better. Assess your environment, contaminants, and specific air purification goals to choose the most effective method.

Frequently Asked Questions

Can Carbon Filters Remove Viruses From Water or Air?

You might wonder if carbon filters can remove viruses from water or air. While they excel at absorbing odors and chemicals, their viral filtration capabilities are limited. For air purification, some high-grade filters can reduce airborne viruses, but they aren’t fully effective alone. In water treatment, activated charcoal can improve taste and remove contaminants, but it’s not designed specifically for viral removal. Always choose specialized filters for effective viral filtration.

How Long Does Activated Charcoal Typically Last Before Needing Replacement?

Did you know activated charcoal filters typically last between 6 to 12 months? Your filter lifespan depends on usage, water or air quality, and household size. You should replace it when you notice a decrease in effectiveness or after the recommended period. To guarantee peak performance, stay aware of replacement timing and follow manufacturer guidelines, as a worn-out filter won’t effectively remove contaminants anymore.

Are There Health Risks Associated With Using Activated Charcoal Filters?

You might wonder if activated charcoal filters pose health concerns. While generally safe, there are toxicity risks if you accidentally ingest large amounts or if the filters contain contaminants. Inhaling dust from the filters can also cause respiratory issues. To stay safe, use filters properly, avoid ingestion, and verify they’re made from high-quality activated charcoal. If you have health concerns, consult a professional before regular use.

Do Carbon Filters or Activated Charcoal Need Specific Maintenance Procedures?

Think of your filter as a trusty garden hose—it needs regular care to keep flowing smoothly. You should monitor the filter lifespan and perform maintenance procedures like replacing or cleaning filters as recommended. This guarantees your system stays efficient and odor-free. Ignoring maintenance can clog the filter, reducing effectiveness and risking airflow issues. Proper upkeep keeps your activated charcoal or carbon filters working at peak performance, protecting your environment.

Can Activated Charcoal Be Reused After Saturation?

When it comes to activated charcoal, reusability concerns arise because once it reaches its saturation limits, it can’t effectively absorb odors or contaminants anymore. You might try to reactivate it through processes like heating, but this often isn’t practical or fully effective. So, it’s best to replace saturated activated charcoal regularly to guarantee maximum performance, rather than trying to reuse it beyond its saturation limits.

Conclusion

So, after all this, it’s amusing how we often think of carbon filters and activated charcoal as interchangeable, yet they serve quite different purposes. You might find yourself buying the “same thing” twice, only to realize one’s perfect for your aquarium and the other’s best in your air purifier. Irony strikes again—sometimes, the best filter is the one you didn’t even know you needed! Choose wisely, and save yourself some confusion.