ULPA filters offer ultra-high-efficiency air filtration, capturing nearly all airborne particles as small as 0.12 microns, which exceeds HEPA filter capabilities. You’ll need ULPA filters in environments that demand the strictest contamination control, such as pharmaceutical labs, cleanrooms, and semiconductor manufacturing. They help guarantee air purity by removing microscopic bacteria, viruses, and spores. If you’re curious about how they improve air quality and when they’re actually necessary, keep exploring this essential filtration technology.

Key Takeaways

- ULPA filters provide higher filtration efficiency than HEPA, capturing particles as small as 0.12 microns.

- They are essential in ultra-clean environments like semiconductor fabrication and pharmaceutical cleanrooms.

- ULPA filters are used when contamination control requires removal of microscopic bacteria, viruses, and spores.

- They are more expensive and require careful installation and maintenance for optimal performance.

- Suitable for environments demanding maximum air purity and compliance with strict standards like ISO 14644.

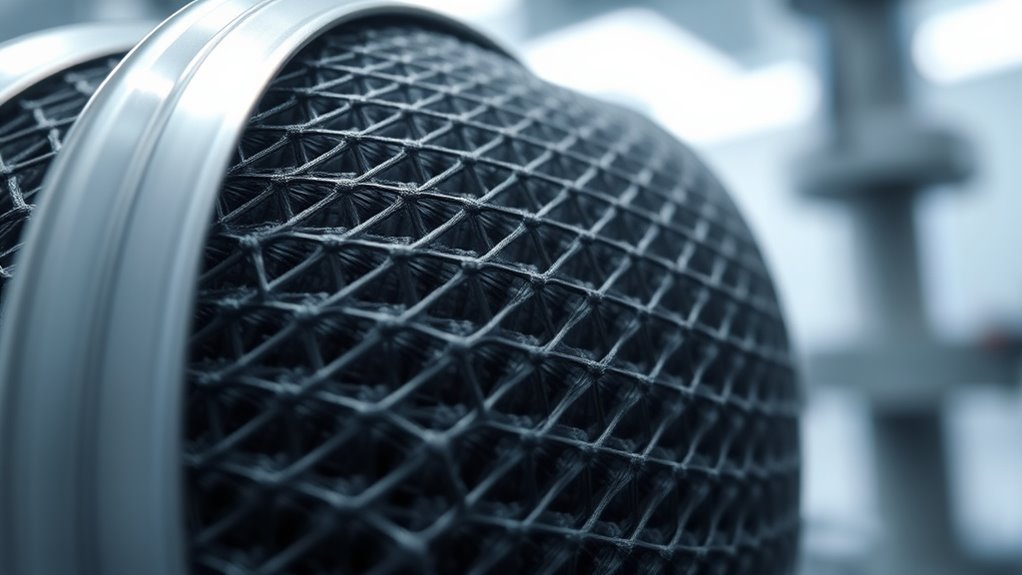

ULPA filters, or Ultra Low Particulate Air filters, are highly efficient air filtration systems designed to remove nearly 100% of airborne particles as small as 0.12 microns. If you’re involved in environments that demand stringent control over airborne contaminants—such as laboratories, pharmaceutical manufacturing, or semiconductor fabrication—understanding ULPA filters becomes essential. These filters surpass HEPA filters in performance, providing an extra layer of protection that aligns with the most rigorous cleanroom standards. When you prioritize air filtration quality, ULPA filters ensure that even the tiniest particles, including bacteria, mold spores, and viruses, are effectively captured, helping you maintain the integrity of your controlled environment.

In cleanroom settings, air filtration plays a critical role in meeting industry standards for contamination control. Cleanroom standards, like ISO 14644 or Federal Standard 209E, specify the maximum allowable particle counts per volume of air, depending on the cleanliness level required. ULPA filters are often employed in settings where the highest classification of air purity is necessary, such as in pharmaceutical packaging or nanotechnology labs. They are designed to trap particles that are considerably smaller than what standard HEPA filters can capture, making them ideal for environments where even microscopic contaminants could compromise product safety or research outcomes. When you install ULPA filters, you’re ensuring your air filtration system can meet or exceed these cleanroom standards, providing peace of mind that your environment remains sterile and contaminant-free.

Additionally, selecting ULPA filters can contribute to better air quality management by significantly reducing potential sources of contamination, which is vital in sensitive industry sectors. You should also consider their compatibility with your existing air handling units and your specific contamination control needs. These filters are constructed with dense, high-efficiency media that require careful installation and maintenance to sustain their performance. You’ll want to regularly check and replace filters to prevent performance degradation, especially in environments where air quality is a top priority. Additionally, ULPA filters tend to be more expensive than HEPA filters, but their ability to achieve ultra-high levels of filtration makes them indispensable in critical applications. Their use signifies a commitment to uncompromising air quality, especially in settings where even the smallest airborne particle can cause substantial issues.

Frequently Asked Questions

How Do ULPA Filters Compare Cost-Wise to HEPA Filters?

When comparing ULPA filters to HEPA filters, you’ll find that ULPA filters generally have a higher cost comparison due to their advanced filtration capabilities. Filter pricing for ULPA filters tends to be more expensive because they trap smaller particles more effectively. Although the initial investment is greater, consider whether the enhanced filtration matches your specific needs, especially if you’re dealing with ultra-fine particles that require higher-grade filtration.

Are ULPA Filters Suitable for Residential Air Purification Systems?

ULPA filters aren’t ideal for residential air purification systems because they’re designed for high-level contamination control in industrial settings. You might find ULPA filters unnecessary for your home, as they could be costly and overkill for improving air quality. Instead, HEPA filters generally provide sufficient air quality improvement for residential use, offering effective particle removal without the complexity and expense of ULPA filters.

What Maintenance Is Required for ULPA Filters?

Think of ULPA filters as the superheroes of air purification, needing special care. You should regularly check the filter for dirt buildup and replace it when airflow decreases or after a certain period, usually around 6-12 months. Follow the manufacturer’s cleaning procedures if applicable, but typically, ULPA filters require minimal cleaning—mainly replacing the filter to guarantee peak performance and avoid contaminant buildup.

Can ULPA Filters Eliminate Viruses Effectively?

ULPA filters are highly effective for virus removal due to their exceptional filtration efficiency, capturing particles as small as 0.1 microns. You can rely on them to substantially reduce airborne viruses in sensitive environments, such as labs or cleanrooms. Their dense filter media ensures that even tiny virus particles are trapped, making ULPA filters a vital choice when maximum aerosol containment is needed for health and safety.

How Long Do ULPA Filters Typically Last?

Imagine a delicate barrier guarding your space’s purity; that’s your ULPA filter. Its lifespan depends on usage, environment, and maintenance, typically lasting 1 to 3 years. Regularly checking filter condition helps determine when to replace it, ensuring peak filtration. Don’t wait until performance drops—by monitoring replacement frequency, you keep air clean and safe, maintaining that essential shield against airborne contaminants.

Conclusion

Just as the phoenix rises from ashes, ULPA filters elevate air purity to new heights, surpassing HEPA standards when precision matters most. When your environment demands the utmost cleanliness—like in cleanrooms or advanced labs—ULPA filters become your steadfast guardians. Recognize their power, and you’ll see that, like a finely tuned symphony, they orchestrate safety and purity with unwavering clarity. Choosing ULPA means trusting the unseen, much like the silent strength of a star guiding the night.