Negative air machines create controlled airflow with powerful fans and high-efficiency filters to trap dust, mold, and airborne particles. You need one during demolition, mold remediation, asbestos removal, or anytime dust and contaminants could spread. They help contain hazards and improve air quality, especially in larger spaces. Choosing the right machine depends on airflow, filtration levels, and noise considerations. Keep it running safely with proper setup and maintenance. To learn more, continue exploring how these machines protect your environment.

Key Takeaways

- Construction-grade negative air machines provide high CFM airflow and advanced filtration essential for large or contaminated spaces.

- They are necessary during demolition, mold remediation, asbestos removal, or fire and water damage cleanup to contain airborne hazards.

- Proper selection involves considering airflow capacity, filtration efficiency, noise levels, and ease of maintenance.

- Using these machines ensures containment of dust, mold spores, and hazardous particles, protecting worker safety and air quality.

- Regular setup, inspection, and filter replacement are crucial for effective operation and compliance with safety standards.

What Is a Negative Air Machine and How Does It Work?

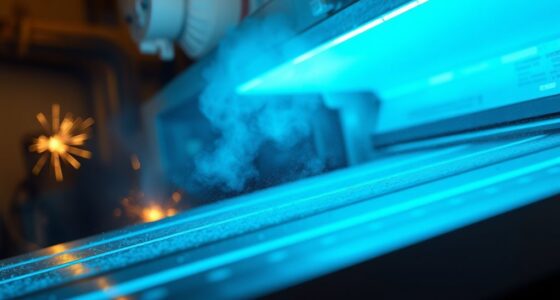

A negative air machine is a specialized device that creates a controlled airflow with lower air pressure inside a space than outside it. This setup influences airflow dynamics, ensuring contaminated air is pulled into the machine rather than escaping. The device uses powerful fans to draw air through high-efficiency filters, which trap dust, mold, and other airborne particles. This process enhances filtration efficiency, making the environment safer during construction or remediation projects. Additionally, effective airflow management ensures that pollutants are contained within the machine, preventing their spread to other areas. Proper negative pressure also helps protect building occupants from potentially hazardous airborne contaminants. As the negative pressure pulls air inward, it prevents pollutants from spreading to adjacent areas. You can adjust the airflow to maintain a consistent negative pressure, optimizing the machine’s effectiveness. Overall, understanding how airflow dynamics and filtration efficiency work together helps you choose the right negative air machine for your needs. Additionally, selecting a device with the appropriate filtration technology ensures optimal removal of airborne contaminants.

How Do You Know When You Need a Negative Air Machine?

Knowing when to use a negative air machine is essential for protecting your environment from airborne contaminants or preventing the spread of hazardous particles. If your project involves demolition, mold remediation, asbestos removal, or any activity that stirs up dust and toxins, a negative air machine can improve air quality and keep contaminants contained. During project planning, consider the scope and potential airborne hazards to determine if a negative air machine is necessary. If your goal is to maintain a safe workspace or safeguard neighboring areas, these machines help filter and exhaust contaminated air effectively. Recognizing the signs—such as persistent dust, odors, or airborne particles—indicates it’s time to deploy a negative air machine to guarantee safety and compliance. Utilizing proper filtration and understanding your equipment options can significantly enhance your project’s safety standards. Additionally, choosing the right testing accuracy for monitoring airborne contaminants ensures that your mitigation efforts are effective and compliant with safety standards.

How to Choose the Right Negative Air Machine for Your Project

Choosing the right negative air machine depends on understanding your project’s specific requirements. Focus on airflow optimization to guarantee the machine can circulate air effectively in your space, providing proper containment and filtration. Consider the size of the area—larger spaces need higher CFM (cubic feet per minute) ratings for efficient operation. Noise reduction is also vital, especially if you’re working in occupied environments or sensitive settings; look for models designed with noise-dampening features. Portability might matter if you need to move the unit frequently. Additionally, check for the appropriate filtration levels to handle your contaminants. Proper airflow management is essential to ensure your negative air machine functions effectively and safely. Understanding construction‑grade filtration can help you choose a model capable of handling more hazardous particles and contaminants, which is crucial for certain projects. Moreover, selecting a machine with adjustable airflow settings can improve efficiency and energy use based on your specific needs. Being aware of filtration efficiency ratings can also guide you toward units that meet industry standards for safety and effectiveness. Evaluating the maintenance requirements of a machine can also impact its long-term operational costs and reliability. By matching airflow capacity and noise levels to your project’s needs, you’ll select a machine that performs efficiently and keeps your work environment safe and comfortable.

What Are the Typical Uses of Construction-Grade Negative Air Machines?

Construction-grade negative air machines are commonly used in various projects where controlling airborne contaminants and maintaining safe environments are priorities. You’ll find them essential during remodeling, demolition, or asbestos removal, where dust containment and HVAC filtering are critical. These machines help keep dust and particles from spreading to other areas, protecting workers and occupants. They are also crucial in mold remediation, preventing spores from contaminating clean zones. Additionally, they are employed in disaster cleanups, such as fire or water damage, to improve air quality. Proper ventilating work areas with negative air machines is essential to ensure the effectiveness of dust and contaminant removal, especially when managing airborne particles. They are designed to create a negative pressure environment, which prevents contaminants from escaping the work zone and contaminating other parts of the building. Utilizing these machines effectively requires understanding their filtering capabilities to match the project’s specific needs. The following table highlights typical uses:

| Project Type | Purpose |

|---|---|

| Remodeling & Demolition | Dust containment, HVAC filtering |

| Asbestos & Mold Removal | Protecting occupied spaces |

| Fire & Water Damage | Improving indoor air quality |

| Construction Sites | Controlling airborne debris |

| Lead Abatement | Ensuring safe dust management |

How Do You Set Up and Maintain Your Negative Air Machine Safely?

To set up your negative air machine safely, start by inspecting all components for damage and ensuring the filters are properly installed. Check the air filter maintenance requirements to confirm filters are clean and securely in place, as dirty or improperly installed filters can reduce effectiveness and pose safety risks. When placing the machine, choose a location that allows unobstructed airflow and keeps the unit away from high-traffic areas or moisture. Position the negative air machine with adequate clearance on all sides to promote proper ventilation. Regularly monitor the machine during operation, listening for unusual noises or vibrations that could indicate issues. Always follow manufacturer instructions for setup, operation, and maintenance to guarantee safe, efficient performance throughout your project. Additionally, understanding filtration efficiency helps ensure your negative air machine provides the necessary level of air purity. Proper placement and ongoing maintenance support optimal air filtration and safety. Furthermore, staying informed about construction-grade filtration standards can enhance your setup process.

Frequently Asked Questions

Can Negative Air Machines Eliminate All Airborne Contaminants?

Negative air machines can’t eliminate all airborne contaminants, but they markedly reduce airborne pathogens and mold spores in your space. They work by pulling contaminated air through filters, capturing most particles and improving air quality. However, for complete removal, especially of viruses or very fine particles, you might need additional filtration methods or specialized equipment. Regular maintenance and proper placement enhance their effectiveness in creating a safer environment.

How Loud Are Negative Air Machines During Operation?

Negative air machines can be surprisingly loud, often comparable to a vacuum cleaner or a hairdryer, with noise levels typically between 60-80 decibels. Think of it as a constant hum that might disrupt conversations or concentration. To minimize this, sound mitigation measures like placing the machine in a separate room or using sound blankets can help. While effective, expect some noise during operation, especially in enclosed spaces.

Are Negative Air Machines Suitable for Residential Use?

Yes, negative air machines are suitable for residential use, especially when you want to improve air quality and guarantee residential safety. They effectively reduce airborne contaminants, mold, and dust, creating a healthier environment. Just keep in mind that some models can be noisy, so choose one with appropriate noise levels for your home. Proper placement and operation will maximize their benefits, making your living space safer and cleaner.

What Are the Energy Consumption Costs of These Machines?

Negative air machines can have significant energy costs depending on their power consumption. You should expect higher energy bills if you run them continuously, especially models with powerful motors. Check the machine’s wattage to estimate your power consumption and calculate your energy costs based on local electricity rates. Using these machines efficiently and only when necessary helps minimize expenses, ensuring you get the protection you need without overpaying on energy.

How Long Can a Negative Air Machine Operate Continuously?

You can operate a negative air machine continuously for as long as needed, maintaining constant air exchange and filtration efficiency. It’s designed to run tirelessly, filtering airborne particles and improving air quality. Keep an eye on the machine’s filters and make sure it’s properly maintained, so it keeps working at peak performance. With steady operation, you ensure a safe environment, fresh air, and effective containment throughout your project.

Conclusion

Whether you’re controlling dust, removing contaminants, or ensuring air quality, understanding when and how to use a negative air machine is key. Recognize the signs, select the right equipment, set it up properly, and maintain it regularly. Stay vigilant, stay informed, and stay safe. By doing so, you’ll protect your space, your health, and your project’s success—because in construction and restoration, proper filtration isn’t just optional; it’s essential.